About

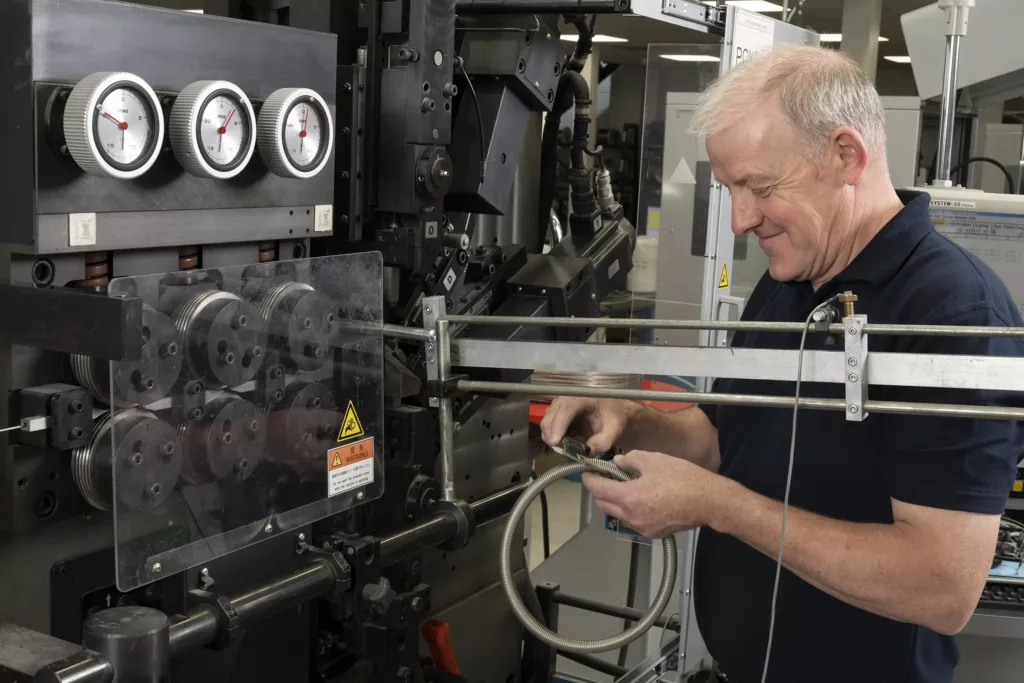

Leaders in Spring Innovation

At Clifford Springs we are obsessed with springs. With years and years of experience under our roof we know springs, inside and out.

Focussing on an innovation led approach helps us improve our spring capabilities. In turn, improvements can be seen in the seals and valves our springs are used in too.

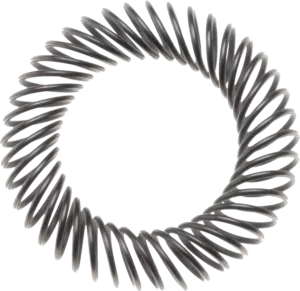

From inventing PEEK springs 20 years ago, to being one of the few manufacturers in the world with the ability to manufacture geometrically complex canted coil, Clifford Springs prides itself on solving customers’ problems using springs.

Our technical advice is freely given, in a timely manner, making it easier for you to do your job. We aim to be as flexible as possible, and will never charge extra to rush jobs through. Whatever you want – if we can do it, we will do it.